SolidCAM Assists CNC Machine Shops in Adopting Additive Manufacturing

We all know that additive and subtractive technology can be crucial resources in the manufacturing sector when they are used together. In many industries, however, 3D printing is still not widely accepted as a production technique due to a lack of knowledge, costs or lack of skilled professionals. SolidCAM, a leader in CAM solutions, aims at facilitating the adoption of additive manufacturing. This is especially important for CNC machine shops that specialize in machining, as they often overlook the many benefits additive systems can offer. Thankfully, SolidCAM’s partnership with Desktop Metal has made additive manufacturing more accessible to machine shops.

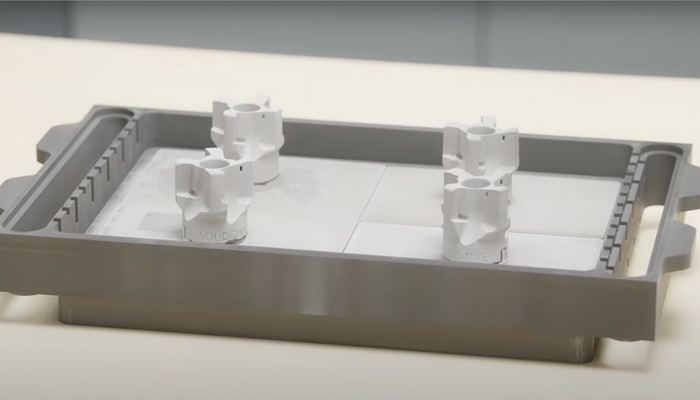

A CNC machine shop refers to an area that employs complex subtractive manufacturing processes. They use cutting technology and CNC machine tools to produce metal or plastic parts as well as other materials. It is therefore interesting for them to think about incorporating additive manufacturing into their production, such as for prototyping or end-use parts. 3D printing has become a vital tool to help companies compete in the market, especially in low- and medium volume production. SolidCAM is the solution. It is easier to adopt Desktop Metal and its Metal BinderJetting technology. Desktop metal’s Shop System is the first additive manufacturing platform that brings metal 3D printing to machine shops. Let’s look at what this process is all about and what benefits it brings to manufacturing companies.

Companies are more competitive when they integrate additive manufacturing.

Additive Manufacturing in CNC Machine Shops

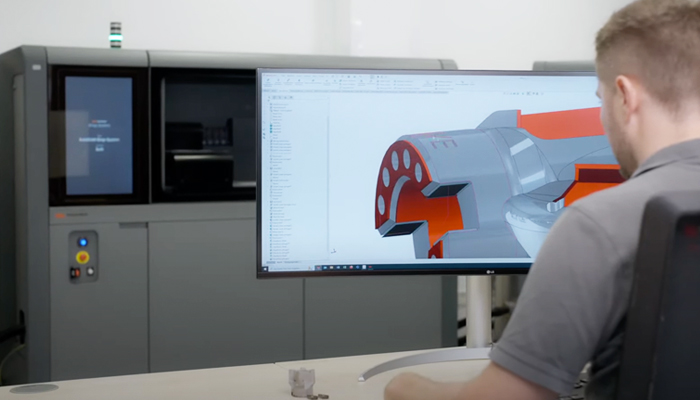

Machine shops often face the problem of suppliers not understanding the requirements and demands of additive manufacturing. It is necessary to find solutions that allow part production to be completed quickly and at a reasonable cost. SolidCAM has a long history of working with machine shops, providing them with CAM software that allows them to program their CNC machines efficiently. SolidCAM can help guide them in finding a process that is both cost-effective and makes sense. SolidCAM and Desktop Metal understand that adoption goes beyond simply installing a metal 3D printing machine on the shop floor. It is crucial to be able to comprehend how to build an efficient additive manufacturing infrastructure within your organization.

This requires that you consider many factors, including how to design for additive manufacturing and which applications are best for 3D printing. You must also know how to manage all aspects of metal additive manufacturing, including file preparation, printing, sintering, and post-processing CNC machining. Experts stress the importance to optimize the whole process and ensure that quality and production standards are met. SolidCAM’s knowledge, together with Desktop Metal’s 3D printing systems, helps to simplify a complex process in order to increase productivity and part yield, with limited operator involvement.

SolidCAM assists companies to adopt technology from start-to-finish

Technology Integration from End to End

It is essential to get started with 3D design before a user can decide to print 3D. SolidCAM’s integrated approach to CAD/CAM provides a significant advantage in this regard. Solidworks and Autodesk Inventor CAD modeling programs can run the CAM functionality. Both of these software have additive manufacturing design capabilities. Users can use the most powerful design tools and the same 3D model to program CNC functions such as Advanced Mill-Turn and iMachining. A new module is being developed by the company for hybrid machines, where 3D printing can be combined with machining. This aligns with Desktop Metal’s holistic approach to additive manufacturing, from creating proprietary metal powders to sintering parts.

Technique is equally important in both subtractive and additive manufacturing. SolidCAM has established centers of excellence which integrate 3D printing and CNC machine machining to address both needs. The goal? The goal? To demonstrate how additive manufacturing can be implemented, and to produce parts for companies who aren’t ready to commit fully. SolidCAM founder and CEO Dr. Emil Somekh says: “Through combining the two technologies, companies can solve complex engineering problems in new and innovative ways. To ensure that the parts meet customer specifications, metal 3D printing still requires post-processing using CNC machining. SolidCAM is positioned as the leader in CAM solutions, adapting its software technology to effectively post-process the growing market of additive parts.”

It is clear that SolidCAM’s manufacturing expertise combined with Desktop Metal’s 3D printing solutions are helping many companies in the adoption of additive manufacturing. Somekh adds that this reinforces the position. “SolidCAM views additive manufacturing as a complement to our 24,000 CNC subtractive manufacturing customers worldwide. SolidCAM CNC customers have the ability to quickly and accurately print complex metal parts.” More information can be found on the SolidCAM website HERE.

What do YOU think about the integration AM into CNC machine shop shops? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: SolidCAM