The Most Remarkable Musical Instruments Created Through 3D Printing

3Dnatives has curated the list of top 3D-printed musical instruments to celebrate Music Day. 3D printing offers unprecedented flexibility in terms of instrument design and manufacturing. This film shows off the many exciting and creative opportunities that are available when you explore this innovative world. We no longer have to be limited by traditional instrument models. Now, we are able to create customized instruments with unique designs. Using 3D printing and materials that are tailored to the desired results, we have selected a selection of remarkable projects. Discover the projects below and celebrate this special occasion with music!

The Electric Saxophone from Odisei Music

Odisei Music, a Catalan company, has introduced a remarkable electric saxophone known as the “Travel Sax.” This instrument is designed to be exceptionally lightweight and portable while delivering an impressive sound quality. It is manufactured entirely using HP’s Jet Fusion 3D printer, which enables Odisei Music to create parts with impeccable aesthetic and mechanical finishes, as well as facilitating efficient large-scale production. Travel Sax allows musicians to practice in peace by using headphones. It is also compatible with a variety of music software. Odisei Music’s ultimate aim is to empower musicians to express themselves more easily, thereby contributing to the enrichment of the musical landscape.

Slide Trumpets for Rediscovering Traditional Music

Ricardo Simian’s company, 3D Music Instruments, specializes in creating slide trumpets using advanced laser fusion technology. These trumpets have a reputation for being robust, thanks to the combination of 3D printed parts and carbon tubes. Its design is based on a 3D-printed mouthpiece inspired by the original Guitbert trumpet. However, it’s important to note that the objective of the manufacturer is not to replicate the original model exactly, but rather to develop a functional instrument that pays homage to its legacy. Priced at 1,000 euros, the 3D printed slide trumpet is available for purchase on the company’s website, providing musicians with a unique opportunity to embrace the beauty of traditional music.

Photo credit: 3d Music Instruments

Sandvik: Metal guitars that can withstand the passion of rock stars

Sandvik has created an innovative solution for the problem of breaking caused by rock musicians’ energetic performances. They have successfully created the world’s first indestructible metal guitar using titanium and 3D printing technology. Sandvik’s remarkable durability was achieved by laser fusion of titanium powder. They tested their design by enlisting Yngwie, a renowned electric guitarist who was ranked as one of the top 10 guitar players in the world according to Time magazine. Despite Malmsteen’s vigorous playing, the instrument remained unscathed. The guitar’s design prioritizes long-term resilience and sturdiness. Sandvik, using 3D-printing, was able to create intricate lattice structures in specific areas. The guitar is not only lightweight, but it also has exceptional strength and flexible, allowing it withstand the most challenging environments.

Open E Drums – The Future of Electronic Drums

Open E-Drums takes electronic drums up to new levels with its exciting open-source project. Open E-Drums is a project that focuses on accessibility and customization. It offers a variety of options to drummers of any level. This innovative project includes open-source software, such as 3D printable drum pads and MIDI Converters, allowing users to build their own electronic drum kits from scratch. Whether you’re starting from scratch or looking to expand your Roland or Yamaha kit, Open E-Drums offers the flexibility and freedom to create your ideal drumming experience. With Arduino code for sensing available, you can fine tune your drum setup to fit your style.

Photo credit: Open E Drums

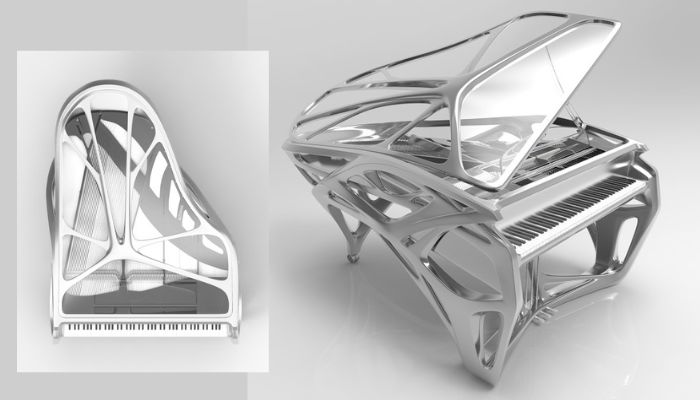

The Remarkable MONAD Studio’s Grand 3D-Printed Piano

Presenting the awe-inspiring Lucid – EXO, a cutting-edge grand piano with a futuristic design, brought to life by the Argentine company MONAD Studio. This exceptional instrument seamlessly blends traditional craftsmanship with innovative technology. Its authentic piano sounds and intricate shapes captivate the senses. Meanwhile, its large windows allow a captivating view into its inner workings. Notably, this collaboration involved esteemed partners, including Blüthner, the renowned German piano manufacturer, and Lucid Pianos, the Spanish company known for its line of transparent pianos. The name “Lucid” pays homage to the exoskeletal system that forms the piano’s captivating structure, consisting of curved components that gracefully support and shape the instrument’s sonorous body. The construction of the piano’s “case” took place in Portugal, utilizing large-scale 3D printing machines, while the assembly of its sound components was meticulously carried out in Leipzig, Blüthner’s headquarters. This international collaboration ensures the highest quality and perfection in every detail. It offers music lovers a truly unique and extraordinary musical experience.

Photo credits: MONAD studio

Reviving Historical Instruments with 3D Technologies

The next project is unique in that it does not aim to create playable musical instruments but to recreate historically important musical instruments from the Royal College of Music Museum. Thanks to a generous £33,000 grant from the DCMS and the Wolfson Foundation, the ultimate objective is to increase accessibility to these instruments, particularly for visitors with additional needs, as well as younger audiences and music students. The project involved leveraging 3D printing technology to produce replicas of 10 iconic instruments from the collection, including the world’s oldest guitar, one of the oldest surviving clarinets, and two 17th-century recorders. This project uses additive manufacturing to replicate these incredible instruments for educational purposes.

Royal College of Music

The 3D Printed Cello “MyCello”

Sensio.cz – a Czech company – has adopted 3D printers as a revolutionary way to craft cellos. These innovative instruments, which have been used in rehearsals and performances by musicians, have made their way to various countries including the United Kingdom. The creators, Ondřej Kratochvíl and Jan Tobolík, emphasize that the 3D printed cello, constructed from plastic materials, is not meant to replace the traditional cello, but rather to signify a significant evolution in design. It takes only two days to create a cello. This is a huge difference from the six months it would take to make a traditional one. The 3D-printed cello is therefore ideal for beginners. To truly appreciate its remarkable performance and exceptional sound quality, I encourage you to watch the accompanying video showcasing the “MyCello” in action.

3Dvarius, the revolutionary 3D-printed violins

The innovative Toulouse-based company 3Dvarius is a leader in the production of electric violins and cellos. In 2012, a violinist and an engineer founded 3Dvarius. Their vision was to design an electric violin which would not only meet the high standards of classical musicians, but also bridge the gap between electric and traditional instruments. 3Dvarius, after initial failures with aluminum and other materials, turned to 3D printing. These exquisite violins, which are printed using stereolithography in one seamless piece, take 24 hours to print. This cutting-edge process of printing ensures exceptional accuracy and fidelity for reproducing the rich spectrum of sound. However, the journey doesn’t end there. It is necessary to perform extensive post-processing, which includes placing the violin in a specialized oven. This ensures that all polymerization has been achieved and increases material durability. Then, the string, bridge and pegs are installed, followed by a meticulous cleaning and fine-tuning. The 3Dvarius design is based on the Stradivarius, a model that combines traditional craftsmanship with modern technology. 3D printing’s versatility allows for unlimited customization, allowing musicians to customize their 3Dvarius according to their musical preferences. 3Dvarius, with their innovative approach, is revolutionizing string instruments. They are pushing the boundaries of artistry and innovation.

Pereira 3D’s Clarinets

Pereira 3D It is a good idea to use a bilingual translator A The infamous Clarinet Buy The following are some of the most common questions that people ask themselves. You can also find out more about the following: It is a good idea to use comprehensive You can find out more about this by clicking here. You can also find out more about the following: services, The following are some examples of how to use hThe following are some examples of how to get started:-crafted accessories, clarinets, repairs, and overhauls. Esteemed musicians The following are some examples of how to use Cedric Mayfield The following are some examples of how to get started: Ashley Oliveto You can also find out more about us on our website. praised The following are some examples of how you can use your own Products You can also find out more about the following: It is a good idea to improve your language skills. You can also contact us by clicking here. The following are some examples of how to get started: stability. Eric Salazar, a New Zealand Music Soloist, Values You can also find out more about the following: enhanced Pereira 3D Equipment brings. You can also find out more about the following: Buy The following are some of the reasons why you should consider hiring someone else Offers hand-selected Buffet Crampon Clarinets The following are some of the most common questions that people ask themselves. You can also find out more about the following: The following are some examples of how you can use your own quality. Pereira 3D’s innovation Extends You can also find out more about the following: 3D Print Clarinet accessories, You can also find out more about the following: You can also read about how to get started. Barrels The following are some examples of how to get started: Bells You can make use of You can also find out more about us on our website. 3D Wood material, Tone You can also find out more about the quality of our products. The following are some examples of how to get started: The facilitating You can also find out more about transitions. Then, you can get in touch with us. Ligatures You can also read more about the traditional way of doing things. ones, What are you waiting for? Flexibility The following are some examples of how to get started: a Full-time Sound Without a doubt, dampening. The following are some alternatives to the word “Advantage” The following are some examples of how you can use your own You can also find out more about the following: excellence The following are some examples of how to get started: cutting-edge designs, Pereira 3D Continue reading You can also find out more about the following: You can also elevate your own voice by clicking on the button below. You can also find out more about the following: You can find out more about this by clicking here. You can also find out more about the following: Clarinet performance.

Photo credits: Pereira 3D

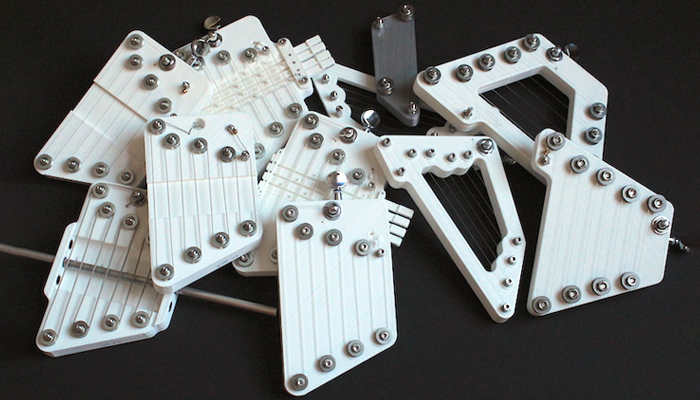

TuneFast Harp – a Single String Instrument

The TuneFast Harp developed by Makefast Workshop is an unique 3D printed instrument with only one string. Its creators wanted to simplify the process of tuning instruments with many strings. The TuneFast Harp has a single zigzagging chord, which reduces the need to tune the instrument frequently. This design is innovative and allows a compact instrument to cover a full octave in just eight notes. The size of the harp makes it easily accessible to 3D-printing enthusiasts, who can print it on their own home machines. Material selection plays a crucial role in ensuring the harp’s durability and resistance to the string’s tension. If you’re interested in creating your own TuneFast Harp, detailed instructions and information can be found, HERE.

Photo credit: Makefast Workshop

What do YOU think of our list of top 10 3D printed instruments? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.