Researchers Have Created a New Rotational, Multimaterial 3D Printing Process

A group of researchers from the Harvard John A. Paulson College of Engineering and Utilized Sciences and the Wyss Institute for Biologically Impressed Engineering at Harvard College have taken inspiration from nature to develop a moderately stunning 3D printing technique. Impressed by the helix-shaped buildings discovered primarily in crops, they’ve designed a 3D printer that’s able to printing with 4 completely different supplies whereby a rotating nozzle deposits a helical filament. To date, the group has 3D printed buildings of various stiffnesses that would have attention-grabbing functions in robotics for instance.

This isn’t the primary time that mankind depends on nature’s conduct to innovate: in 3D printing, we frequently discuss biomimicry and there are a lot of tasks imitating the buildings that encompass us. One instance is the lattice buildings that reproduce bee nests. On this explicit venture, the concept is to be impressed by the helical shapes present in all organic methods, reminiscent of crops and our personal muscle tissue. In reality, it’s our proteins that assemble themselves and that, by taking this helix form, triggering their contraction. It might subsequently be attention-grabbing to have the ability to design a construction able to contracting due to the properties of the fabric. That is the monitor explored by these researchers.

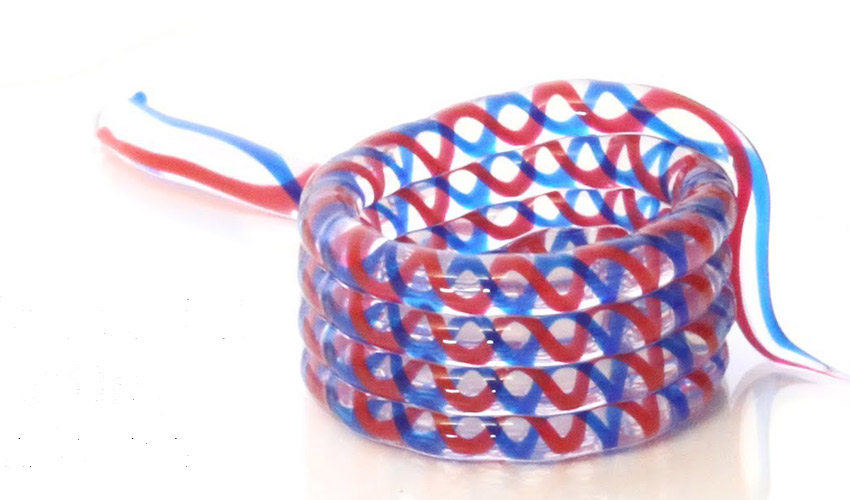

The helical form is built-in into the deposited filament (photograph credit: Harvard John A. Paulson College of Engineering and Utilized Sciences)

How Rotational Multimaterial 3D Printing Works

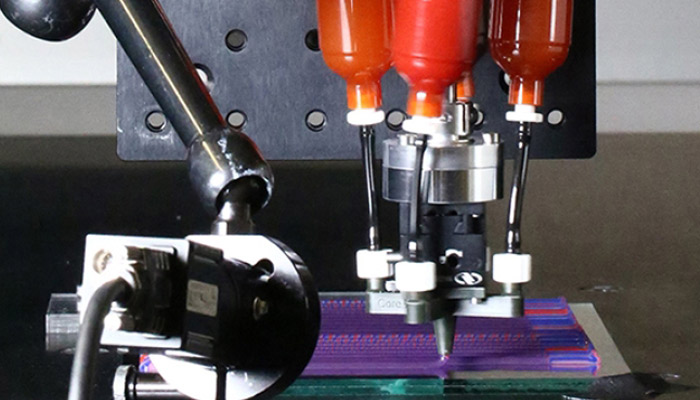

The imagined additive manufacturing resolution makes use of 4 completely different ink cartridges – much like giant syringes. They’re related to a posh rotating nozzle that, because it strikes, creates a filament with helical properties. Natalie Larson, creator of the research, explains, “Rotational multimaterial printing permits us to generate practical helical filaments and structural lattices with exactly managed structure and, finally, efficiency.”

So far as functions are involved, the researchers would be capable to print buildings able to contracting when subjected an utilized voltage. This contraction can be programmable in response to the contractile response of the actuator filaments. They may additionally play on the rigidity of the 3D printed buildings: the bottom matrix can be versatile and inside, there can be adjustable inflexible inks, like a steel spring in a mushy mattress. The group explains that this might be helpful for creating hinges in mushy robots, for instance.

The 3D printing platform consists of 4 cartridges (photograph credit: Harvard John A. Paulson College of Engineering and Utilized Sciences)

And the analysis continues to be in its infancy! The sphere of potentialities is huge and we will’t wait to see what the subsequent developments might be! Natalie Larson concludes, “By designing and constructing nozzles with extra excessive inside options, the decision, complexity, and efficiency of those hierarchical bioinspired buildings might be additional enhanced.” Within the meantime, discover extra info HERE.

What do you consider this new rotational multimaterial 3D printing course of? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to join our free weekly E-newsletter right here for the most recent 3D printing information straight to your inbox! It’s also possible to discover all our movies on our YouTube channel.

*Cowl Photograph Credit: Harvard John A. Paulson College of Engineering and Utilized Sciences