EOS Has Developed a Solution for Support-Free Metal 3D Printing

Today’s metal 3D printing is targeted primarily at professionals. It opens up new possibilities for them in a variety of industries. Grand View Research’s study found that the market value for metal 3D printing in 2022 was already $4.06B. However, this value will rise to $22.60B in 2030 according to Grand View Research. DMLS, which stands for Direct Metal Laser Melting, is a notable example. EOS patented this process in 1994. It is now used across many industries, including aerospace, medicine, and automotive.

DMLS technology, just like other additive manufacturing technologies requires support structures (supports). EOS has created a variety of solutions that allow metal 3D printing complex geometries using a drastically reduced number of support structures to take the technology further and make it more accessible for all users. Metal 3D printing supports can be costly in terms of time, material and labor.

Metal printing on an EOS quad laser system (photo credit: EOS GmbH).

The Challenges Associated with Support Structures for Metal 3D Printering

It is normal for DMLS users to need to add support depending on the part they are using. It is only then that it is possible to 3D-print geometries with much more complicated and detailed designs. For example, it is possible to design overhangs less than 30 degrees and entire bridges or recesses. Without support structures, all of these geometries could deform.

Supports can be added to the design during the process. They are then removed manually after 3D printing or automatically. We can see that adding supports is required for many parts. But, they also present some problems which are reflected in the costs. This innovative technology allows 3D printing with metals to be done with less support structures thanks to the DMLS process.

EOS Supports Customers Implementing Support-Free 3D Printering

Three factors are essential to ensure that you can also enjoy the benefits of 3D printing without support: the process, the tools, and the relevant know-how. EOS provides an excellent example of support-free DMLS3Dprinting using an impeller. Because of its complicated geometries, it normally relies upon support structures. Support-free printing is more difficult because each impeller can have large differences in diameters, blades, and covers. EOS says it is crucial to share the required knowledge at all levels.

You need to think additively in order to make metal 3D printed with limited supports. This can be accomplished by a variety of training and consulting. It is important to have this knowledge in order to design, lay out the components on the build platform and even choose the right material. Smart Fusion, which should be soon available, is an essential piece of the puzzle for support-free metal 3D printers. This tool can adjust the laser’s energy input to the geometry and reduce thermal stresses. The reduction of support structures in metal-based additive manufacturing can lead to shorter build times as well as less effort in post processing and material savings.

“Even though we are pushing the boundaries of what is possible in support-free 3D printing, you are still dealing with real physics and therefore not everything is possible. Our solution is a game-changer. We are both excited about the potential of the technology and so are our customers, both pilots and customers who have already tested it with us. I would say challenge us – we are ready to innovate metal 3D printing together,” Davy Orye, Additive Minds Consultants team leader, expands.

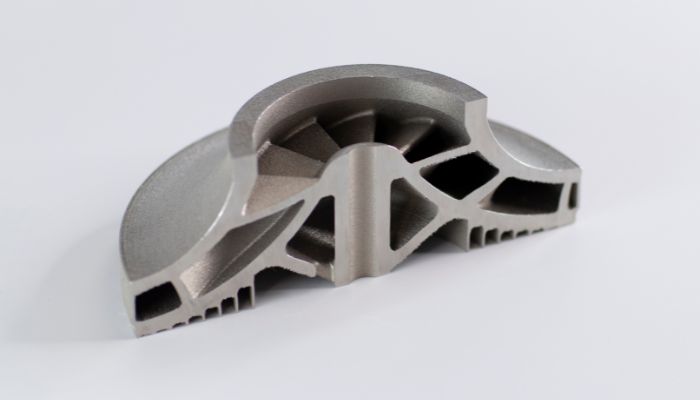

The impeller was made in an optimized 316L manufacturing process on an EOS M 290, without any internal supports. It also achieved a cost reduction (35%). (photo credit: EOS GmbH).

This is a result of the attractiveness of metal 3D printers and their support-free additive manufacturing. A cost analysis of the impeller shows that 35% could be saved. These savings are mainly in post-processing, material, and construction time. However, costs and effort to design a process without support structures went up from 8 to 14%. Additionally, 3D printing without support is more cost-effective and produces less waste. This makes it safer to work as users don’t have to do any post-processing like cutting or grinding. You can find all the details about support-free metal 3D printing HERE.

What do you think of the possibility of metal 3D printing using fewer support structures? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: EOS GmbH (hip stems produced by optimizing the Ti64 process on an EOS M 300-4 for 100% support-free manufacturing).