Cloud Factory On Their 3D Printed Silver Jewelry

3D printing allows for the creation of delicate and original jewelry designs. Cloud Factory, which is made up of professionals from various industries, is one player in this field. They help creators, brands and gamers to develop real jewelry with additive manufacturing. With just an idea the team takes care of the design, 3D modeling, sending samples, packaging of your jewelry ordered with your brand logo … all without the need for a minimum order, or inventory problems. We spoke with them about their company and how they produce unique silver jewelry.

3DN: Can you introduce yourself and describe your connection to additive manufacturing?

Our team is made up of people from different backgrounds who have come together to create something new. Our founder Taavi has been working in the field of additive manufacturing for over a decade now – developing operating systems for FDM 3D printers and teaching students and fellow startups the benefits of 3D printing. Marek, co-founder has a PhD. He worked at TalTec University Tallinn as a scientist to resolve different problems with industrial 3-D printers before he got into the startup world. Kati, the sole female founder, worked as a marketing manager in one of the oldest and largest nightclubs in Baltics. She dealt with promoters and artists and kept the club updated on all things that interested them. A degree in creative entrepreneurship, specializing fashion design, is also my qualification. Erik joined us as an affiliate marketer, investor gold, and cryptocurrency expert. Our growing business needed all aspects covered by us together. Taavi was particularly interested in additive manufacturing, and the possibilities it offers to showcase its benefits.

Cloud Factory team

3DN: How did Cloud Factory’s adventure start?

Taavi was fortunate to meet a world superstar, who fled the United States for a quiet retreat in Estonian forests, far from the paparazzi. Taavi was very excited to be able to create some metal jewelry items for him and, together with Marek, they got a government innovation grant and developed fast, high-quality parameters for the university’s industrial 3D printer. Then, Taavi asked me to join the team to help with branding, marketing and design. I was immediately able to see the potential of this business beyond the star he met. From there, we began creating samples for artists performing at the nightclub that I managed and for other artists visiting Estonia. We used contacts from my previous work in the entertainment sector. We quickly saw the amazement in the artists’ eyes when we presented them with necklaces and rings with their logos and design elements. This business model immediately won them over, so we decided to expand the business from having a product store to not having our own sales channels and becoming a “white label” manufacturing service for many artists, influencers and jewelry brands.

3DN: How to make 3D printed jewelry

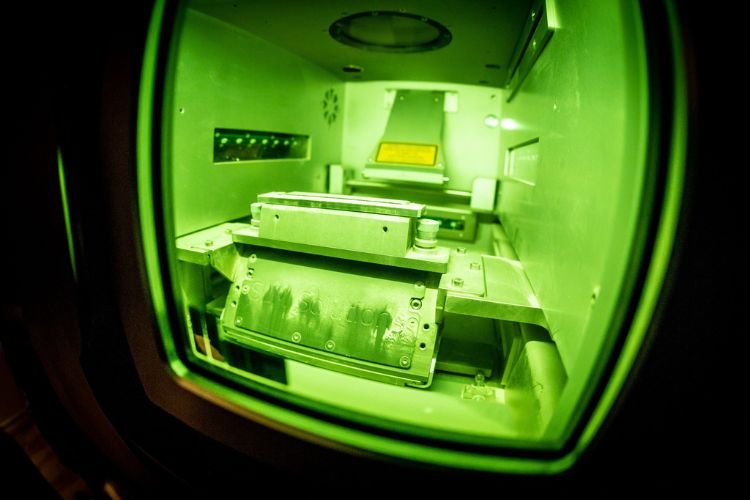

We only currently work with sterling silver 925. Our partner buys scrap from around the globe and turns it into silver powder, which we then use to 3D print direct metal. Directly 3D printing jewelry pieces from 100% recycled sterling silver is possible with a selective laser melting process. Many people have asked us why we chose this printing technology. The simple answer is that it is the most resource-efficient, since it does not require complex manufacturing steps like traditional methods. It automates our manufacturing processes, saving us time, material, and the earth. It’s the technology that best suits our grand vision to build a network worldwide of fully automated, sustainable jewelry printing centers. This will offer a unique, fast, and carbon-free service for brands, creators, and individuals.

Cloud Factory uses an industrial 3D printer for silver jewelry production

3DN: What benefits and limitations can you see in metal 3D printing

Technology offers many advantages over the previously mentioned. This technology allows us to produce super-fast and flexible products, customize, limit runs, and new product launches in just days. It also helps us fully automate this labor-intensive sector. Complex 3D models are still difficult to create. This is the only problem at present. It can take several days to complete more complex designs in order to begin the sampling process. That’s why we are also working on development that can help us automate the part of product development that requires a lot of manual work: converting 2D designs into 3D. This would enable us to sign up new customers much faster than ever.

3DN: How do YOU see additive manufacturing’s future in the jewelry industry?

I think the process that Cloud Factory uses will definitely be a key element of the industry within a decade – relative to the increased restrictions within the industry to stop polluting actions, traditional manufacturers are looking for new ways to be more planet friendly and to meet the desires and of the next generation’s customers.

3DN: Last words for our readers?

Cloud Factory is a pioneer in the sustainable production of fine jewelry. The jewelry industry is a lucrative one, but its potential has been limited for centuries by the need for extensive production knowledge, upfront payments, and long development processes. We are changing the game. We want to make the jewelry business more accessible to future generations. Our goal is to make it affordable, traditional and fun for everyone. Cloud Factory can be found HERE.

What do you think of Cloud Factory? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.